Manufacturer of aluminium fruit ladders and fiberglass ladders

Contact FINE, your expert for aluminium or FRP ladders

Regardless of the type of aluminum or FRP ladders your company needs, FINE offers complete capabilities for a complete solution that is ready to be shipped or inserted into a production line.

We're here to help with

- FREE CAD/CAM design support

- Manufacturing programs

- Real-time production tracking

- Product troubleshooting and diagnostic assistance

Our Ladders

From garden repairs to fruit picking, FINE fruit ladders will help you. From circuit repair to high voltage line work, the FINE fiberglass ladder will keep you safe! FINE Ladder, offers you the most comprehensive ladder solution

FRP Platform Fiberglass Ladder

Fiberglass Ladder

Fiberglass Foldable Ladder

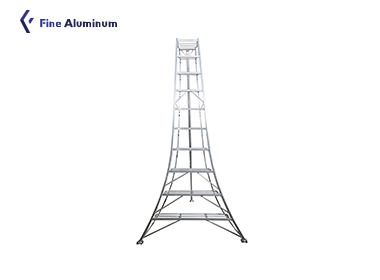

Tripod Ladder

Aluminum step ladder double sided standing elevating ladder with bottom supports

Fruit Harvest Ladder

Fruit Picking Ladder

Agronomic/garden welding aluminum ladder

Orchard Ladder

Want to know more about our products?

Fiberglass Ladders and Aluminum Ladders

We have the manufacturing and assembly team to maximize accuracy and dramatically reduce production time. It is the control over all processes – from selecting the ideal raw materials and alloys, to world-class fabrication, finishing and assembly, to custom packaging of your finished product – that enables FINE to provide you with cost-effective, high quality aluminum products.

Why Choose Us

It’s very simple – all you have to do is email us a drawing, and we’ll take care of the rest.

Our Factory Advantage

- 20 years experience in ladder production.

- Ladder exported to South America, North America, Europe market.

- Factory has ISO-9001 quality management system, strictly control ladder production and quality.

- We accept OEM/ODM, Full range of ladder customization services for you.

Our Product Advantage

- Huge 150KG weight rating, stronger than others on the market.

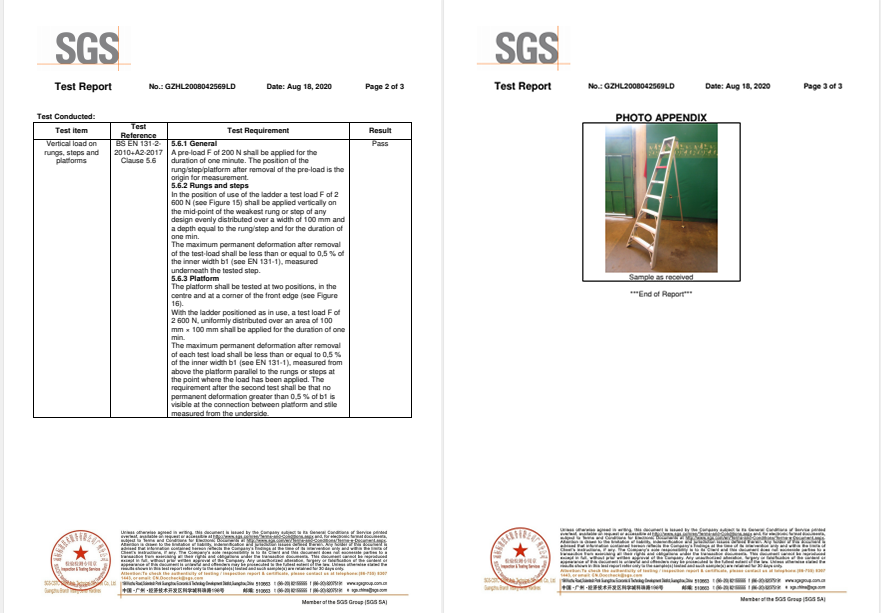

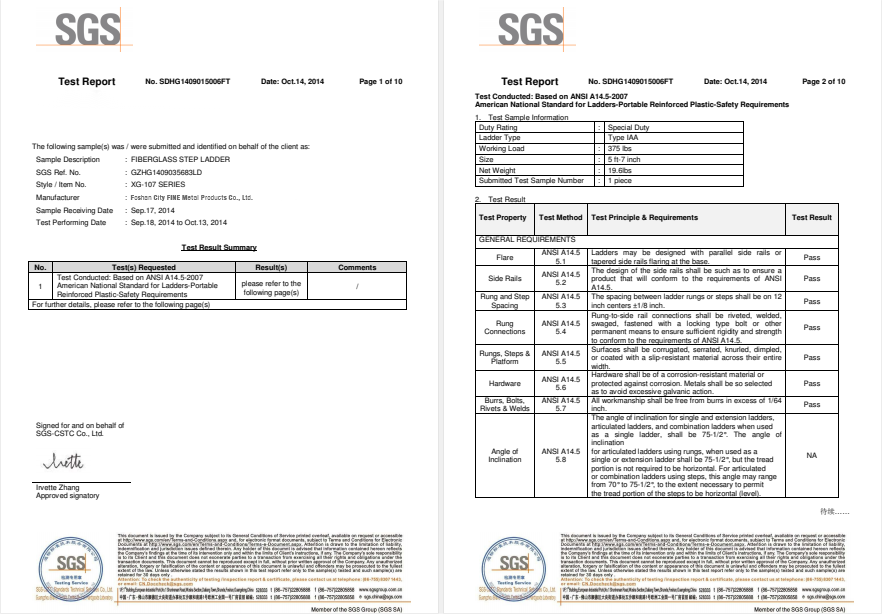

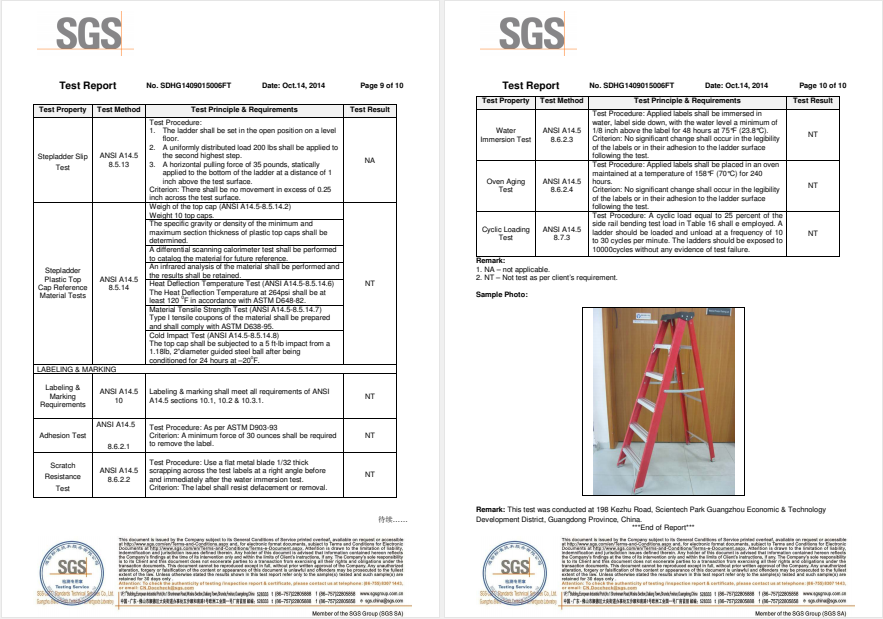

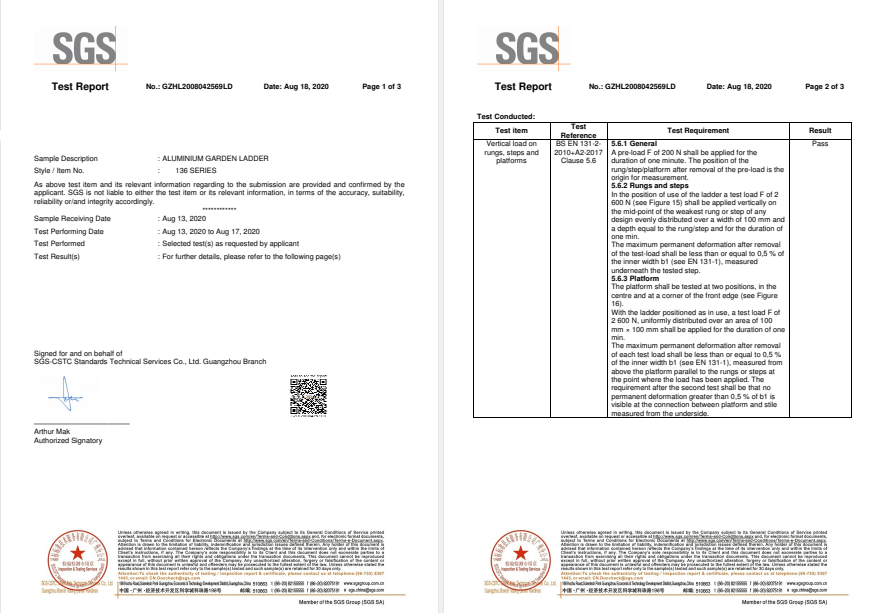

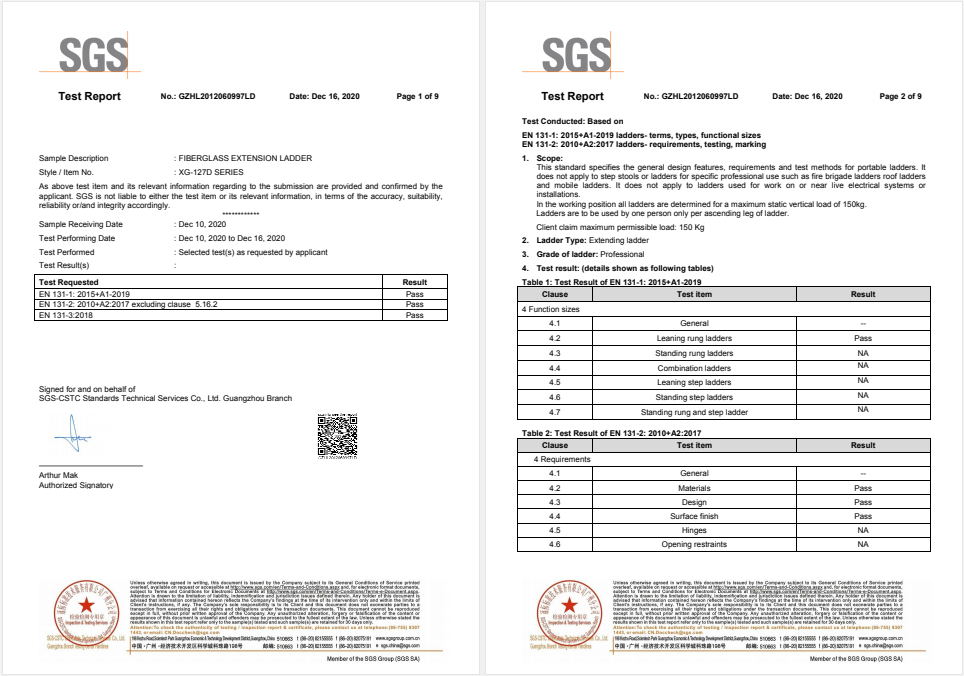

- EN131 Safety Standard certification, ANSI,GB and other quality certificates to reassure you.

- Our FRP ladders Insulated and non-conductive up to 35,000 volts.

- We usually use thicker and better materials to make only ladders.

- We have a large stock and can deliver goods 3~7 days after placing an order.

24/7/365 Engineering Consulting Service

- Custom Profile Design and Maintenance

- Internal Design and Build of Fixtures

- Desired Surface Treatments and Machinings

- Part Design for Manufacturability

- Alloy Development Capabilities

- Packaging Instructions

Need a Consultation?

We look forward to hearing from you. If you have a question or any request you want to discuss, please start a new case, and we will give you the help you need.

About the Ladders Production

With multiple facilities and multiple capabilities, FINE is able to deliver exactly what clients need, serving as a single-source supplier for all manufacturing requirements, catering to a wide array of industries. For clients, it’s like having five unique and capable suppliers under one umbrella, but as only one entity on their approved supplier list.

Raw Material Guarantee

Using high quality FPR material, can withstand high voltage 35KV high voltage, prevent electric shock, to ensure worker safety

Aluminum Extrusion

Aluminum raw materials from the factory production, from the source to ensure the quality of ladder

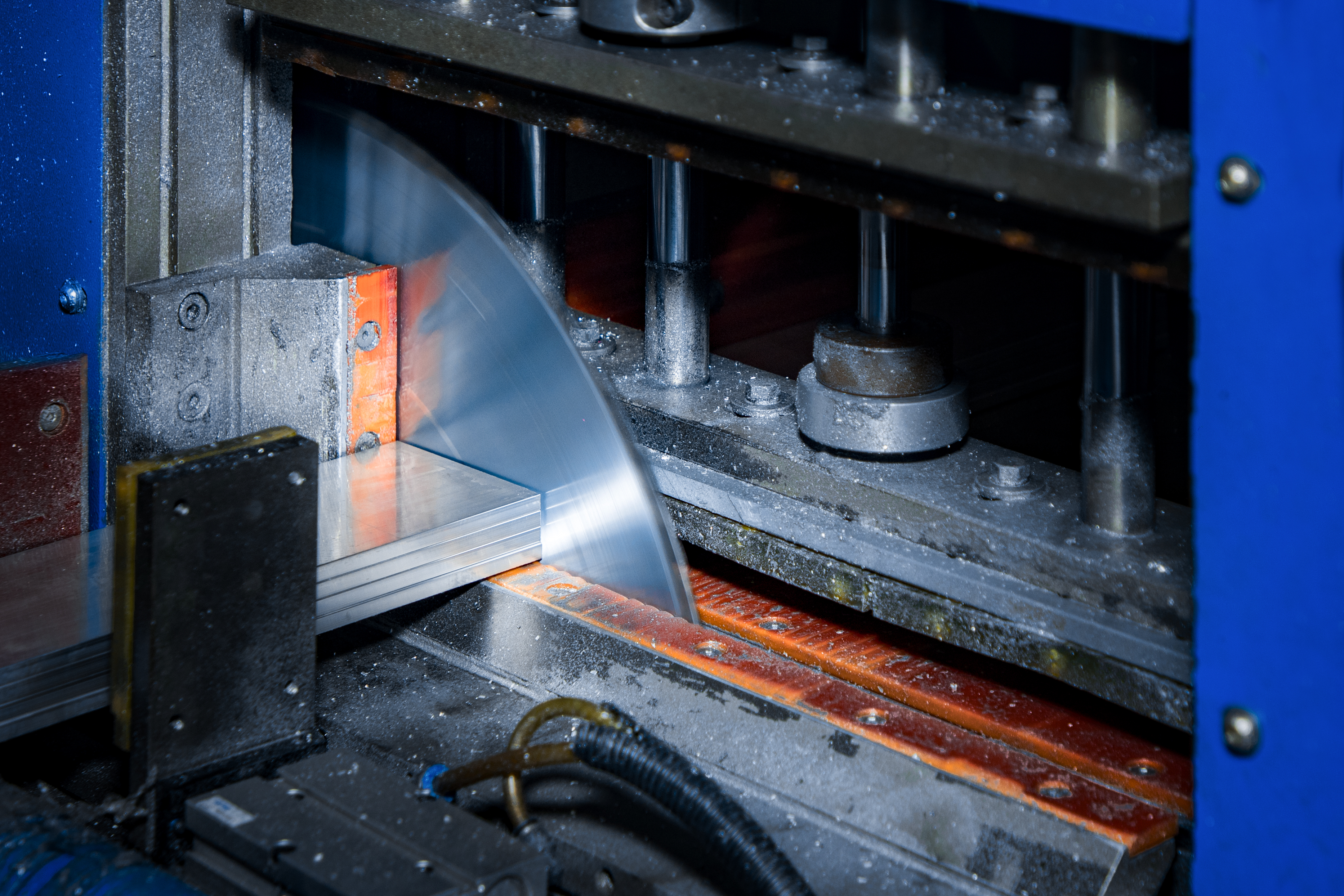

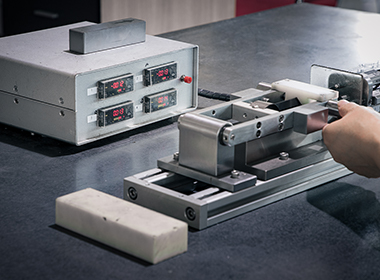

Material Cutting

Precision cutting machine is used to cut raw materials and reduce errors

Rivetting

The company has 10 semi-automatic riveting equipment, which can efficiently complete the production and make the ladder more firm.

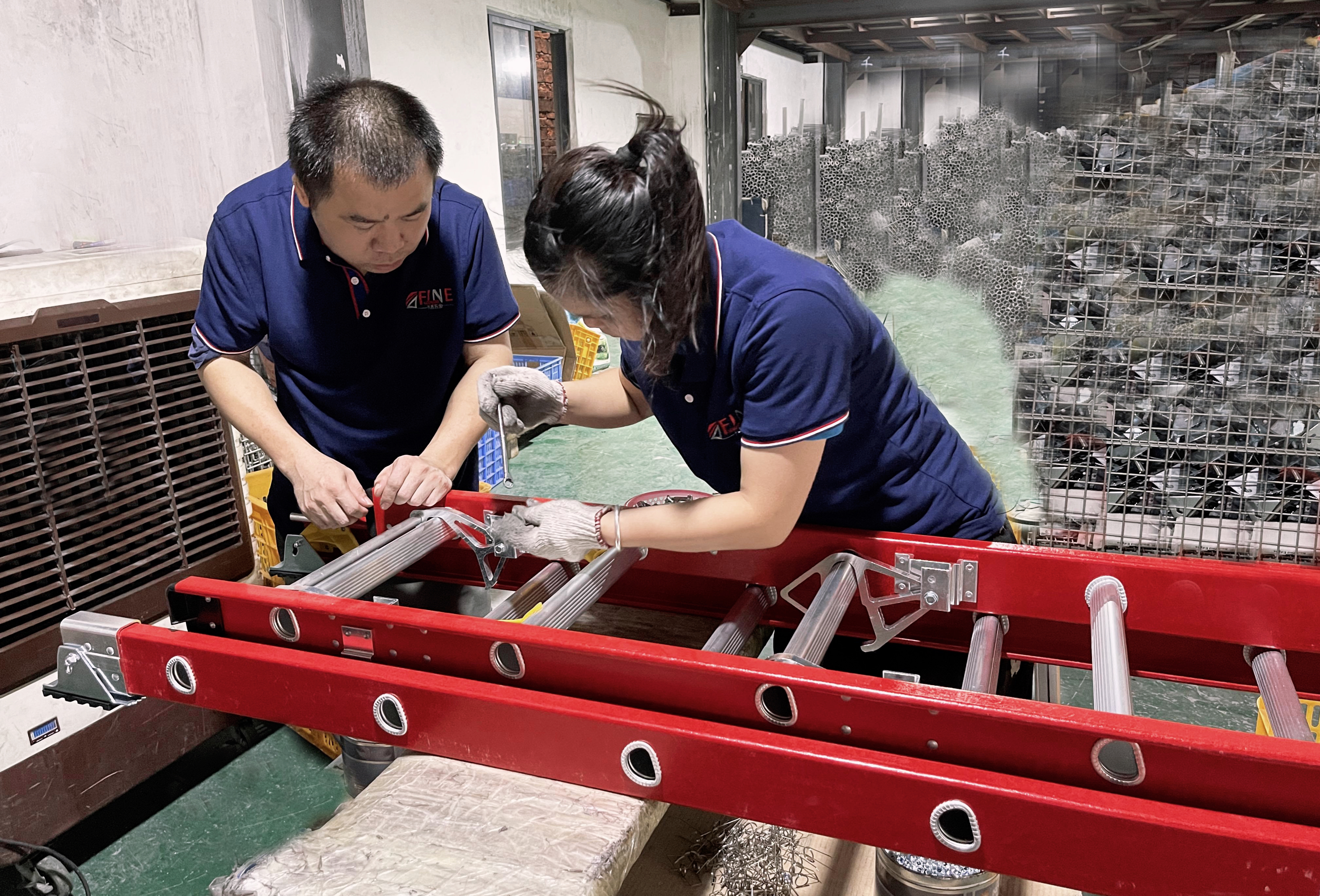

Assembly

Professional assembly workers complete the ladder assembly and conduct quality inspection to ensure that the ladder is of high quality before delivery.

Large Stock

The factory has a large quantity of Stock, to ensure the rapid delivery of customer orders, reduce the production waiting time, the average delivery cycle of 3-7 days!

FINE Quality Assurance Department

Where We Exclusively Focus on Quality

Our Quality Assurance (QA) department primarily exists to monitor all of the FINE on-going production, and on-line engineering support functions to ensure they comply with the published engineering procedures & standards, and to professionally answer your queries and address all your doubts.

Compliance monitoring is conducted by a dedicated team of auditors with the objective to continuously monitor the effectiveness of the engineering department’s processes and procedures to ensure that all corporate and regulatory requirements are met.

Detailed Quality Inspections on Program

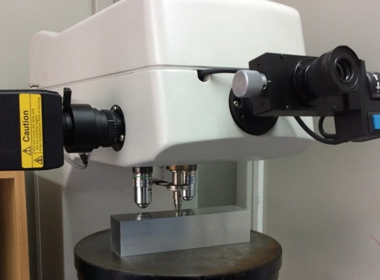

Spectral Analysis

In order to comply with the alloy-specific properties, spectral analyzes and controls are made in the spectrometer device by taking samples of the molten aluminum and the billet after the casting.

Dimensional Inspection

Wall thickness, sizes and locations of holes, curvature, length, width are just some of the measurements critical to extruded profiles. It is extremely important to verify that your parts comply with industry standard tolerances.

Hardness Test

We verify that aluminum and other extruded profiles possess the required hardness specific to your product type. Hardness is a critical property used to determine the suitability of aluminum extrusions for their standard applications.

Visual Defects Check

Appearance inspection is used to find foreign particles, stains, flaws and chipping and to prevent outflow of defective extrusions. We leverage 100% inspection with your samples as basis of the pass and fail criteria for this process.

Corrosion Resistance Test

This procedure subjects the product to the appropriate test methods to determine its ability to resist corrosion. With this test, we ensure the spontaneous formation of the protective coating.

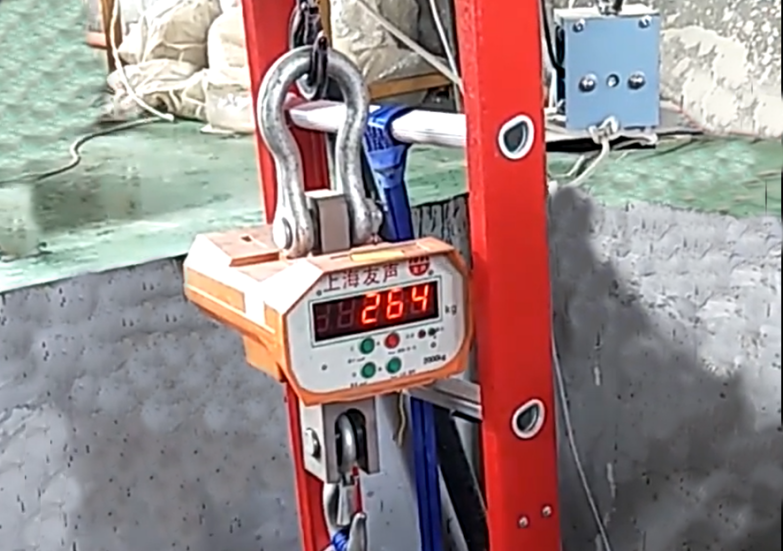

Ladder Bearing Test

A strict and precise load bearing test is carried out for each ladder before delivery. Each step of the ladder must bear more than 150kg before being approved for shipment

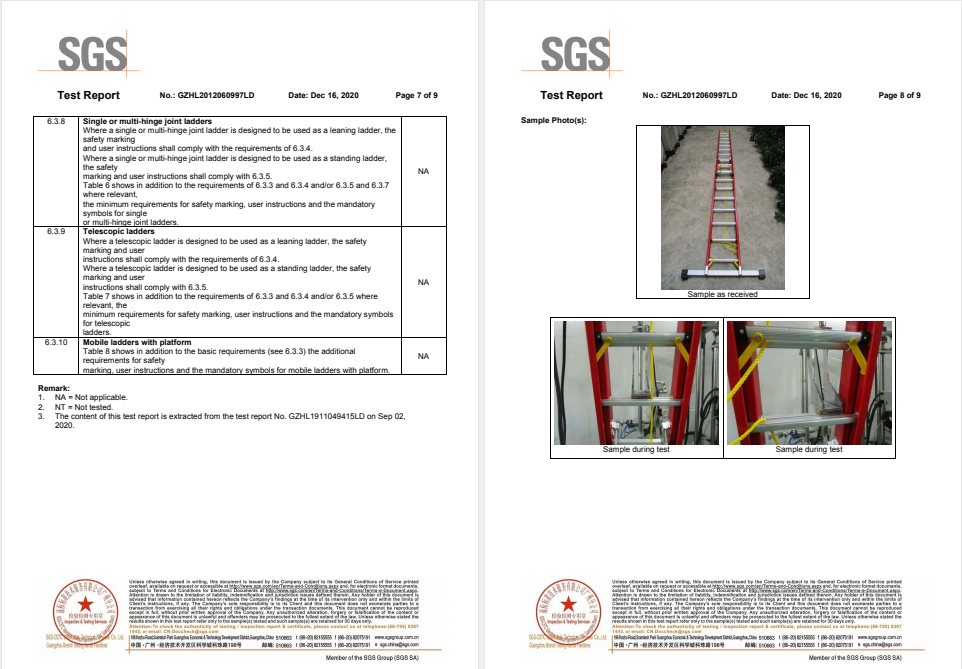

Our Certificate

Key Industries Served

Fire Escape

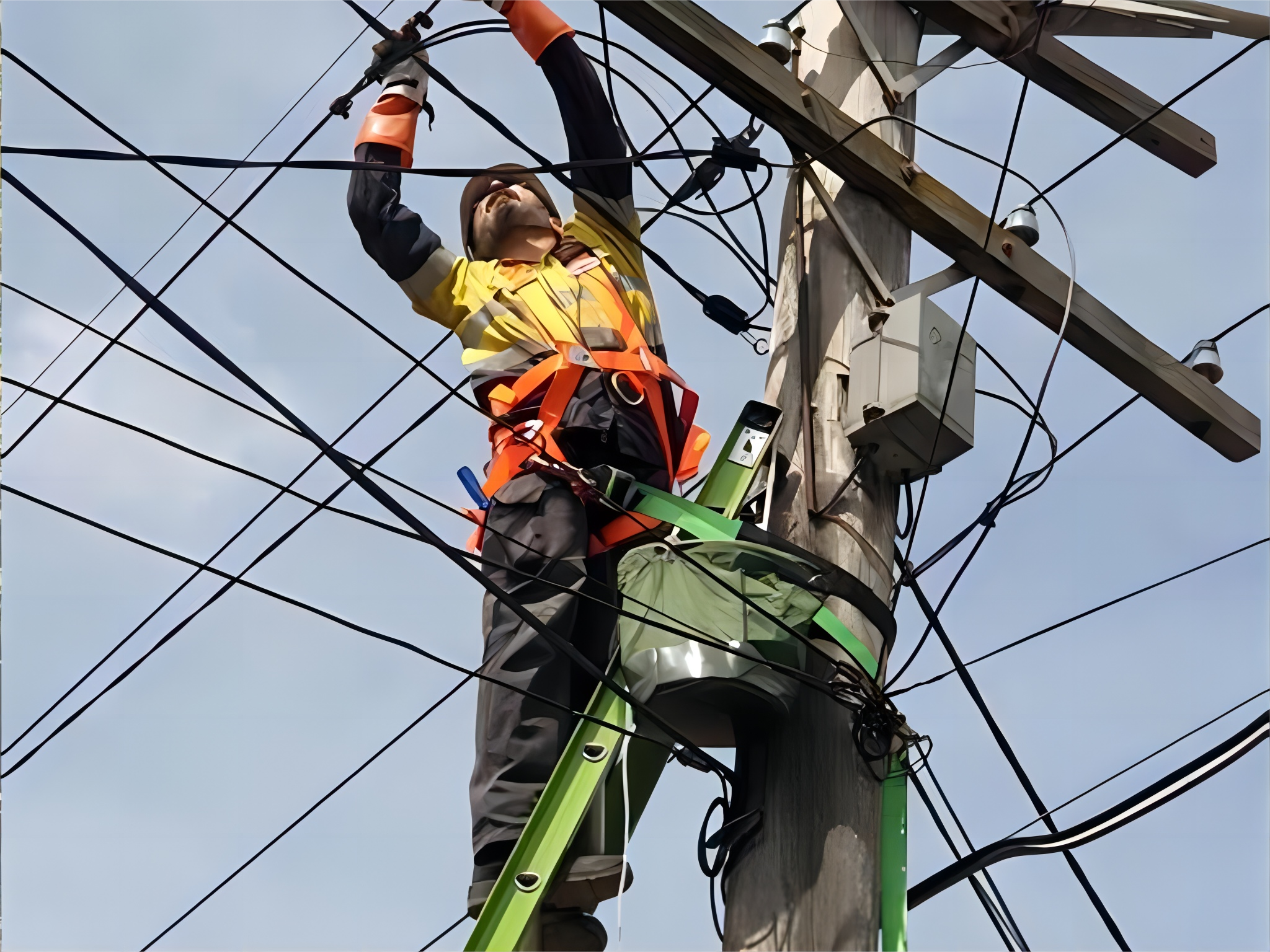

Electrical Use

Industrial Use

Household

Fruit Packing

Garden Work

We definitely serve more industries including yours!

Feel free to contact us 24/7, see what we know about your market.

Our Showcase Examples

High voltage line installation project in Ecuador

In 2022, FINE supplied fiberglass extension ladders to a high-voltage line installation project in Ecuador. FINE’s fiberglass ladders passed a series of quality and safety tests that led to the partnership. FINE has been promoting the development and production of FRP extension ladders in accordance with the principle of quality first. Our FRP ladders are made of high quality insulated FRP material, which can withstand 35KV high voltage, and have been certified as EN131,ANSI, GB, etc., to ensure that each ladder can protect workers from electric shock. FINE is a glass steel ladder source production factory, from quality, service, price to ensure the rights and interests of customers, FINE is looking forward to cooperating with you! For more information, please contact us!

Cherry picking season in Chile

Since 2018, FINE fruit ladder has been helping cherry harvest in Chile. A large number of Chilean farmers and distributors have purchased fruit ladder from FINE ,It has exported more than 100 containers to Chile and neighboring countries. Before October every year, FINE will prepare a large number of spot fruit ladder to ensure customers’ demand for the product and ensure fast shipment! Many customers have reported that FINE’s fruit ladder has good quality and favorable price, which leads to long-term cooperation. FINE hopes to help more farmers and distributors, and help the development of fruit industry in South America. FINE is looking forward to cooperating with you!

©2020 FINE Aluminum Co.,Ltd All Rights Reserved.